Complete Flexible Packaging Solution

Manufacturing

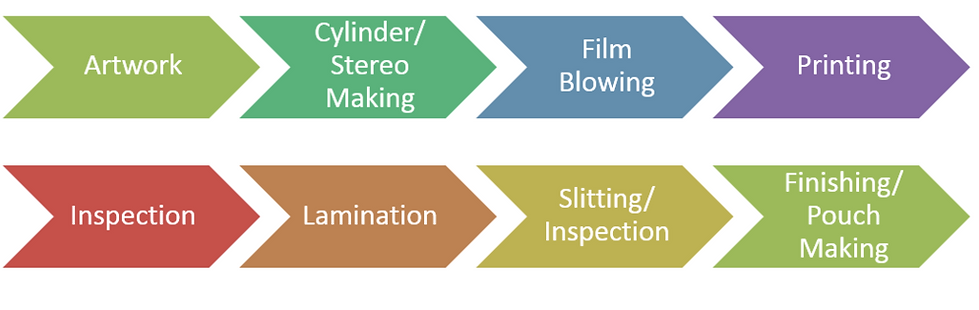

Our team of experts work tirelessly to provide our customers with the best quality and economical solutions for all their packaging solution needs. Our Manufacturing Processes has been shown in brief in the image above and has been explained below:

Rotogravure Printing

-

Capable of printing high definition graphics

-

Surface printing done on various kinds of plastic films which can be transparent, metallic (silver foil), white opaque films and also on paper

-

Reverse printing on plastic films which can then be laminated with other materials such as plastic, metallic film, white opaque film, paper and multi-layer lamination

-

Experts in handling small and large order quantities

-

High speed printing machines used for optimum sharpness and coloring of the product.

-

All our products are customized as per client and product needs

Adhesive Lamination

-

To enhance barrier properties, multi-layer lamination options available

-

High speed lamination machines of both solvent base and solvent-less lamination variants available as per product needs

-

Capable of producing laminates for several high end applications such as retort packaging, vacuum pouches, burst-resistant films, etc

-

High heat and chemical resistant or ability to freeze and everything in between

Pouch & Bag Making

-

We provide pouches to a wide range of markets based on each individual products needs

-

We can manufacture all types of flexible packaging pouches including retort pouches, profile pouches of various customized shapes and sizes, spout pouches, etc. For detailed information on pouches and its types, uses, etc; click here

-

Possible to create high barrier properties, heat and chemical resistant pouches, pouches with freezing ability, etc

-

All our pouches are made with food grade materials

Strip Lamination

-

First in the industry to introduce strip lamination

-

A wide variety of combinations possible to laminate in strips on various portions of the wrapper

-

Possible to strip laminate at either sides or center as shown in the image

-

Can use metallic film (silver foil), or white opaque strip lamination to get the desired result

-

Offers advantages of transparent with metallic or white opaque finish at the same time

-

Image is an example where front of pouch is metallic and rest is transparent to show the product inside